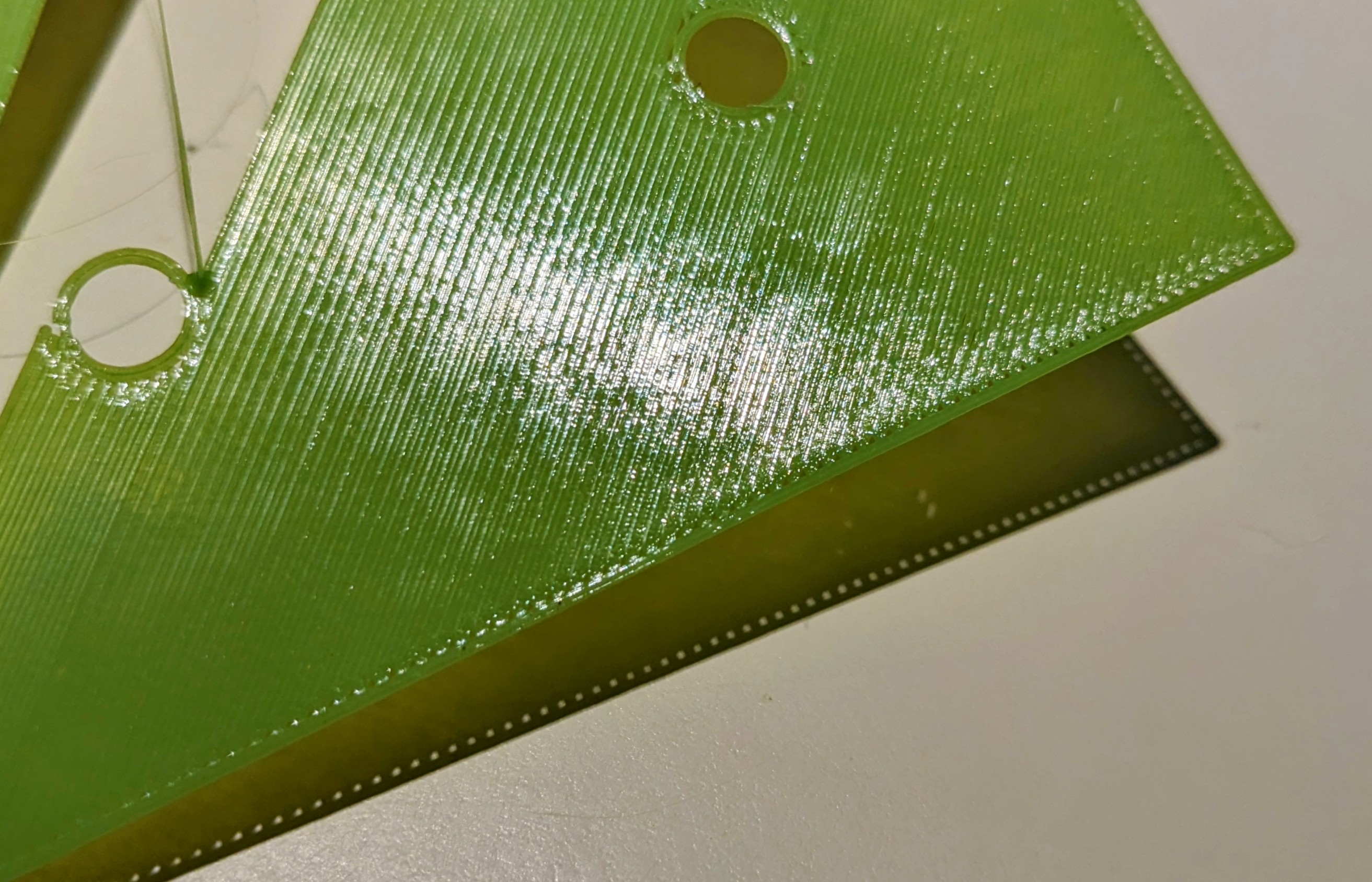

Flashforge creator pro 2 with PLA, standard quality preset, textured removable magnetic bed on the build plate.

The first lines are straight, but as it makes more parallel lines to build the layer, it starts to develop a scalloped pattern. This creates issues with smoothness when it fills back to join it from the other side later. I’ve leveled the build plate, although I suspect it’s not perfectly flat and maybe slightly higher in the middle. Is this my problem? It appears to have the pattern even away from the middle if that makes sense.

Might be too close to the bed

To elaborate a bit, it looks like over extrusion. Do you have a first layer calibration procedure you’ve used?

This is my attempt at calibrating the first layer. I don’t know if there’s some other process I should be using (while I’m fairly technical, I’m new to 3D printing)

If you look around you can find some pretty good tests to characterize all the different features that contribute to good performance. Usually they include using a feeler gauge at several points, and printing certain test shapes in different areas. I don’t have one at hand, since I’m on mobile. Can you describe how you leveled it already? If you’re looking for something to try immediately, I’d try printing at 10 and 20% less flow in the first layer and see how it behaves. Based on that, you can adjust the offset if necessary.

I think this could be the case but I just calibrated it twice and it still does it.

In the case that is an uneven bed, where the middle is slightly high/convex, how do people fix that?

You could fix that by shimming the print surface with paper. I don’t recommend that. You could also get a mesh leveling sensor. It’s technically a workaround, but it works. But it is very hard to believe that your bed is this heavily warped. It looks like the nozzle is generally too close to the bed and the squeeze out accumulates. I’ve had this problem before. I would recommend releveling the bed.

Would you mind also saying what printer you are using?

This is a flashforge creator pro 2 (in original comment). I’m not sure how to characterize the distortion, but the standard leveling routine puts the extruder in 3 locations near the screw adjustment. After adjusting spacing with a sheet of paper (included, calibrated thickness), it puts the extruder down on the center. The center is always higher than the 3 calibration points, often significantly.

Well then I have bad news. You will have to get your bed straight, be it by replacing or some sanding on a flat quartz block. Maybe you could even mill it. One last test I would run is trying to print without the bed heater just to see if the warping gets any better.

A hackier solution is mesh leveling, but in your case it will still produce parts that aren’t flat.

Also back the nozzle off from the bed by about 0.05-0.1mm in the meantime to get some semi usable results.

This is my favorite guide to start with, it’s not necessarily specific to Simplify3d: https://www.simplify3d.com/resources/print-quality-troubleshooting/

Your picture looks kinda like the over-extrusion picture to me.

I have also found the orca calibration guide helpful even if not using Orca because it has some explanatory photos: https://github.com/SoftFever/OrcaSlicer/wiki/Calibration

Probably too close to the bed. The gap between your nozzle and your printing surface isn’t big enough, so some of the filament isn’t able to escape and builds up in blobs. Check if the patters’s any worse/more noticeable towards the middle.

In the case that is an uneven bed, where the middle is slightly high/convex, how do people fix that? I’ve calibrated it twice, but I think it’s still too close in the middle while the standard calibration locations (front center, back left, back right) are perfect

Glass bed mods (glass is always dead flat) or careful adjustments of screws and tramming of the bed, depending on your printer design. Or find a way to sample more points when leveling the bed to compensate for the unevenness. (I have a Snapmaker 2, which shipped with a firmware bug relating to levelling that wasn’t found for quite a long time. Those were the most common fixes and mitigations.)

Glass is not always flat speaking as someone who just swapped their stock glass bed due to warpage (>0.4mm). My new aluminum bed is now within 0.01mm from side to side.

Ignore the people saying overextrusion unless every single layer has issues like that. It’s almost certainly bed leveling issues: you’re too close. When you run your first layer calibrations you’re looking for a test patch that is smooth to the touch. If you have sharp ridges you’re too close, bumps between the lines: too far away.

If you’ve got your test patches all coming out golden and are still having issues that’s another story but in most cases of new printing foibles it’s bed leveling.

+1 on this. The wobbly stuff on the side is just being squished out to the side.

Just want to clarify that it’s actually the Z-offset that’s bad not bed leveling. Bed leveling is just ensuring the bed and extruder are perpendicular (squared) to each other. The Z-offset dictates how far the nozzle is from the print surface.

My bad, misspoke there. You’re right that it’s Z-height not bed leveling.

I tend to think of them as the same because they’re so inter-related when it comes to issues but they are distinct.

I have both problems in different locations in the same test print first layer (see the second photo I posted).

What I’m concluding is that when the calibration locations (front center, left/right rear) are level at the ideal height, the center of the build plate is too high. This is either due to convexity of the build plate OR droop of the extruder due to very slight bending of the beam it travels on. I don’t know how to fix either of these problems.

Result of lowering the bed - perfectly deposited at the middle, underextruded at the edges

It could be a slicer thing. Gap infill settings should be looked at.

Also calibrating pa and flow might help. You need to calibrate these for every filament ideally.

Manually adjusting the bed or just tweaking z offset? If you’re not using offset I could try that in small increments. It looks like you’re really close tho.

That’s not very underextruded on the edges, and doesn’t seem indicative of bed warping IMO.

Which slicer are you using? If you’re using PrusaSlicer the setting you’re looking for is under Advanced > Extrusion Width > External Perimeter

Other slicers will also have this option just might be called something else.

Bump that up by .02mm or so and you’ll probably be golden.

For reference on a 0.4mm nozzle my external extrusion width is 0.45 for external perimeters.

You might also need to bump up the infill/perimeters overlap coefficient by a few percent.

Too tight back it off.