Hey,

Still fairly new to this hobby and have lots of ideas but I’ve got a snag with a few prints now and was hoping someone could help me work out what I’m doing wrong.

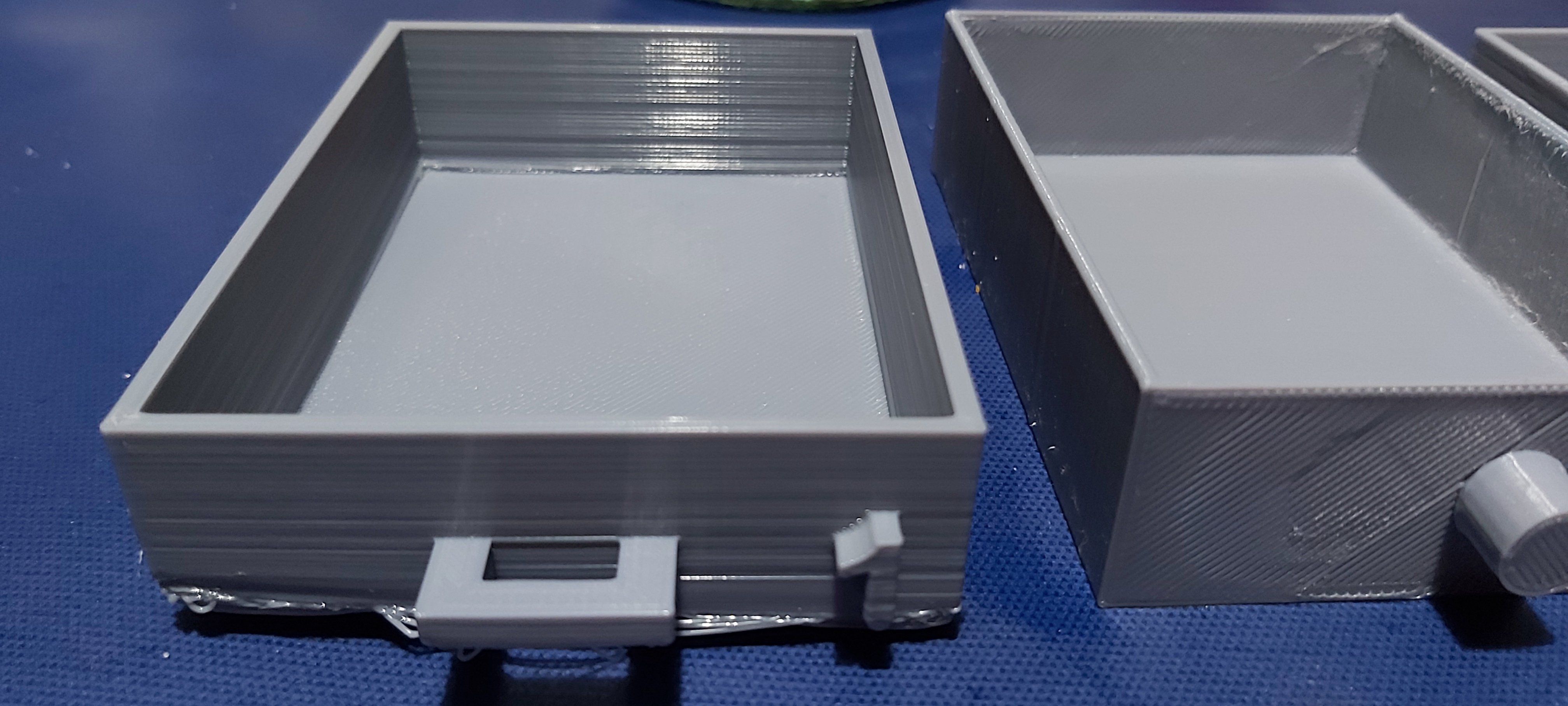

The project is small trays for a custom advent calendar but as you can see the corner on the second picture has lifted massively.

This has happened before with a different print too and I never solved that issue either.

Using an Ender 3 Pro with some generic filament from amazon, hot end at 200C (goes stringy any higher), bed was 50C for this print I think.

Any help would be wonderful :)

The biggest issue is that your corners are lifting from the bed during the print. Fixing this is usually a combination of making sure the bed is clean and adding a brim to increase adhesion. Maybe messing with temperature and cooling fan settings for the first few layers.

Second is things look a bit over extruded. This could just be due to the corner issue though so fix that before any other changes.

I’ve given the bed a good clean now that I’ve found my supplies. Had to hide everything when the niblings visted and forgot where they went. Gonna see how things work out now it’s been cleaned properly and look into over extrusion.

An easy trick is to spray the bed down with hairspray. This is what I did with my old warped glass bed and it worked great to promote adhesion.

So my son and I figured out that a few °C higher bed temp combined with cheap hairspray completely fixed out adhesion issues with PLA corners. Good bed leveling while the bed is at temp is crucial. DO NOT DO IT COLD.