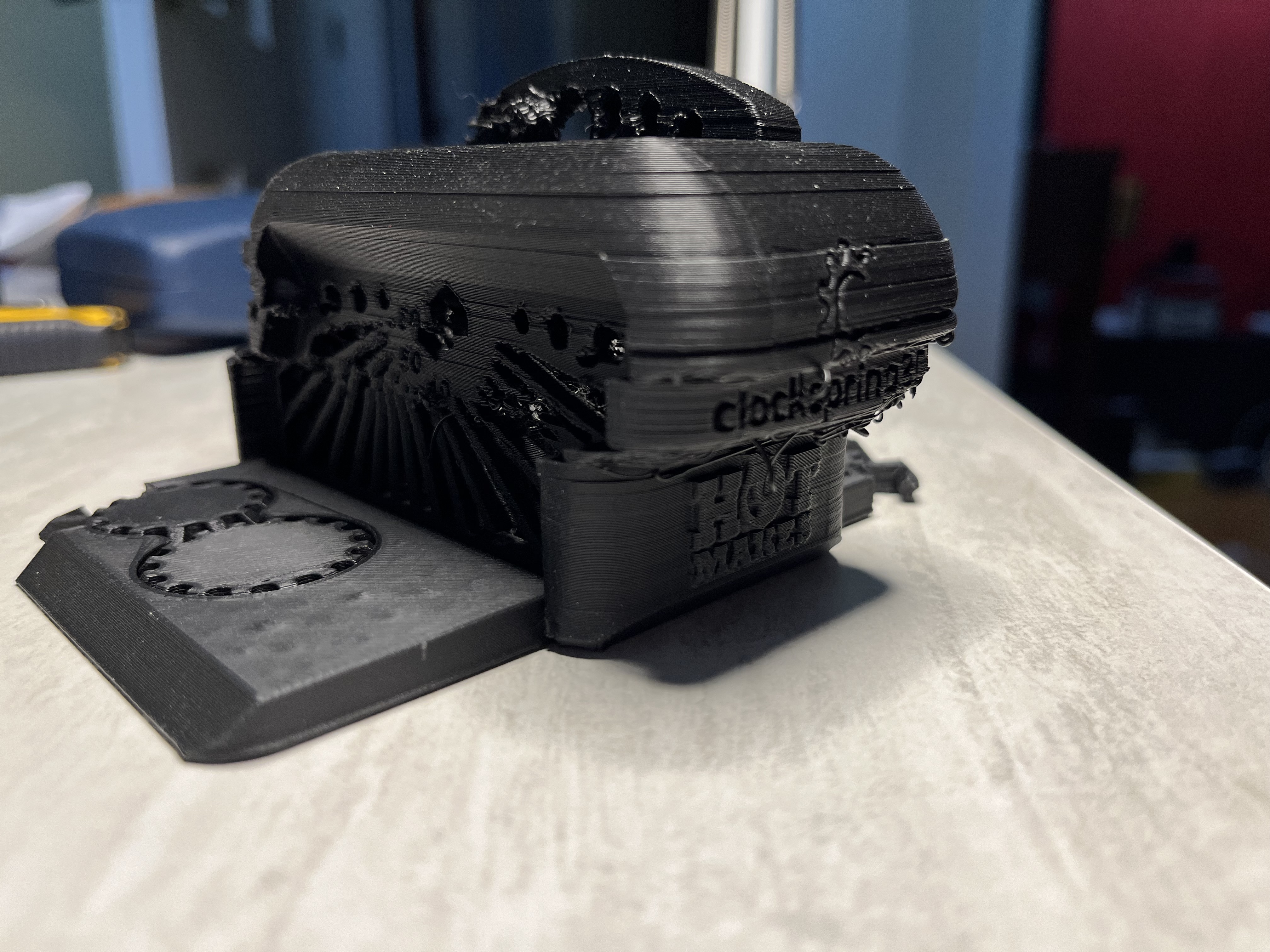

This is a cry for help. I have a Monoprice Voxel which is basically a Flashforge Adventurer 3. Owned for about 3 years now, and still have only a slight idea as to what I am doing. I have been successful with small prints, little thin walled custom functional prints, and they do fine. Trying to print anything longer than 3 hours and I start having issues. I printed a torture toaster and attached is the result. I have never had layer shift like this. Was wondering if anyone out there had any pointers or tips for this printer and pla prints? Are there any other testing prints I can use to help tune and hone in on a perfect print? Good resources for using these testers to tune your prints? Thanks in advance!

I have worked through a TON of troubleshooting on my previous PLA printer(Voxelab Aquilla). The toaster torture test is a beast of print, and it is meant to fail and find the limits of your printer. I would start with much simpler tests. Have you done any simpler temp tower or chep cubes? Or any of the bed level prints? Share photos of some other prints so we can get a better idea of what all is going on.

I am not familiar with how monoprice printers work - but what slicers(s) have you tried/used? Are you leaving default speeds/temps? Is it always the same filament?

Thanks4nothing is right, this is not a model for tuning, its more like a model to prove you tuned it :)

Bed leveling squares, temp tower, flow tower, calibration cube, retraction test. That should be enough, but later on you can look into pressure advance and resonance calibration.

Its better to make your life easier by tuning model/orientation/settings with goal to avoid problems. Dont try the opposite, its easy to force printer to failure.

If your prints fail after 3 hours consistently it can be that your stepper driver is overheating and skipping steps. Easy fix, but that was just a guess, its better if you provide picture of failed print. Are you experiencing layer shift on other models?

+1 to the skipped steps discussion. Those offsets are from the print head somehow getting stuck and not moving when the stepper driver commands a move. Reasons can vary but often they are mechanically related.

One very basic test is to move the head with your hands through its entire travel range on both axes (with motors off ie M84 or printer off) and feel the resistance to motion. Steppers of this size are not particularly powerful; you can overcome their force with your hands.

Another possibility is that the acceleration is set too high: a fast direction change puts a lot of force on the motor. Try setting your acceleration really low, like 100, in the slicer and see if it still behaves that way. If not then there’s your handle on a parameter to tune.

The poor behavior in the toast is probably a different parameter that needs tuning. I suggest getting the layer shift problem fixed before worrying about anything else.

I second this, but even small overextrusion can make bumps that cause collision with nozzle and therefore skipped steps. There are many other scenarios where you can have 0 issues with hardware and still failures like this. Id first start with simple models and make sure hardware is fine, then move on to more advanced models/tuning. Maybe OP just have bad slicer settings or it can be just low vref on stepper driver or lose belt pulley. But yeah, if axis doesnt move smooth dont look further, fix that first