Hey y’all, I managed to hack together a printer from scratch and I’m struggling to get it to print well. It’s a CoreXY system that’s being controlled by a Octopus 1.1. Dual z screws, the works.

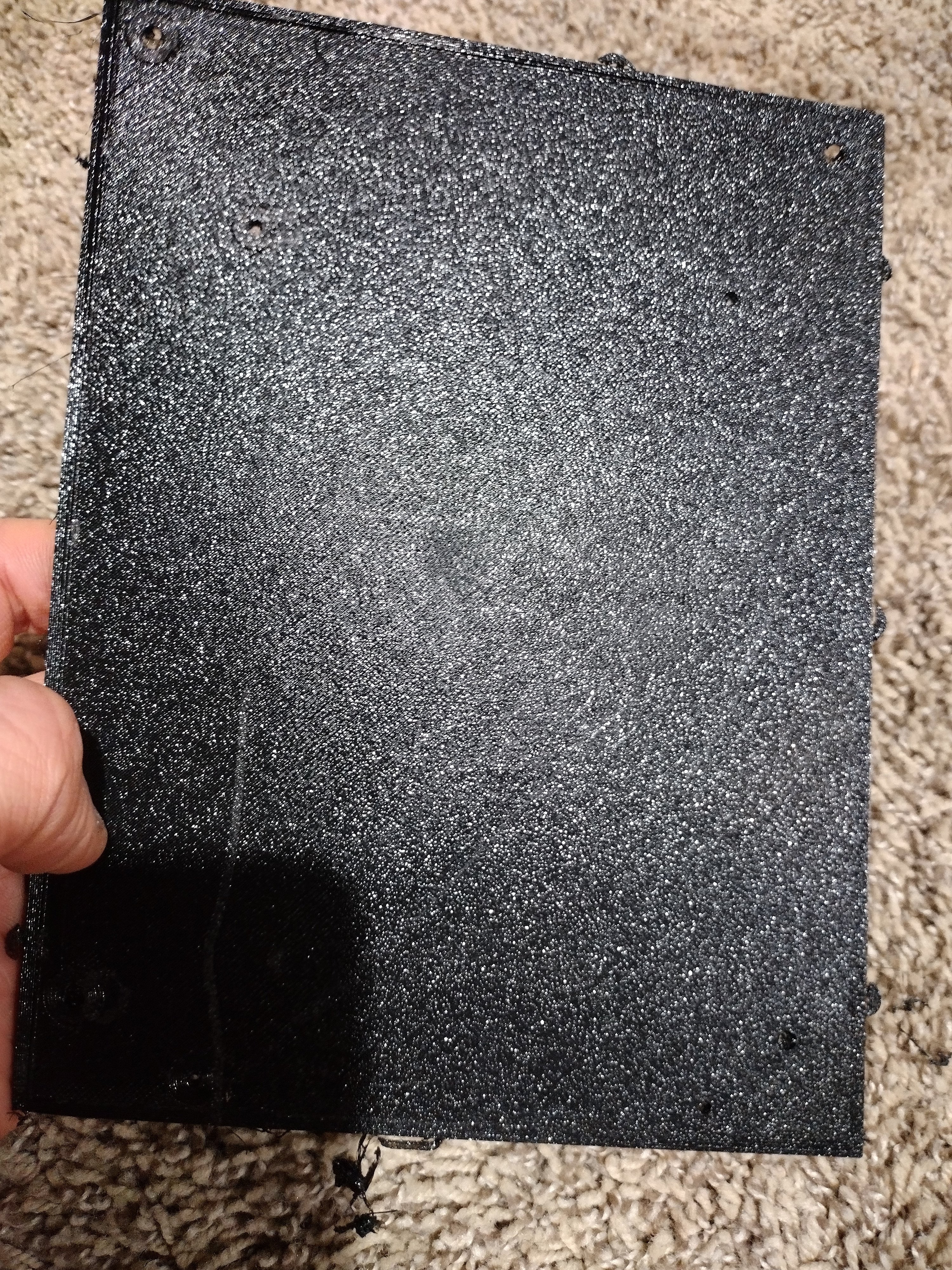

I have it moving under it’s own power and all. It’s able to actually print, but the results are atrocious.

I’m just trying to diagnose what’s wrong here.

The bottom/first layer actually looks kinda good. It’s just completely shredding subsequent layers.

Any advice would be appreciated!

Yeah this is a good call to check. Can you even just squirt filament into the air consistently?

Yep! It actually extrudes just fine. I’m starting to wonder if maybe my z axis e-steps are just slightly off and it’s enough to compound over the course of the print. It seems to hit a certain spot and start grinding itself into the print, which suggests that it might not be moving up enough per layer.

It looks like you’re under-extruding and/or clogging. If you can get filament through your nozzle in air, but not while printing, I wonder if you have enough tension on your filament? Extruder emperature variation as you move around might be another possibility. Not moving correctly in z would cause your parts to mushroom and is easy enough to check by homing, moving the nozzle to say z10, and then measuring the gap.

Good luck!